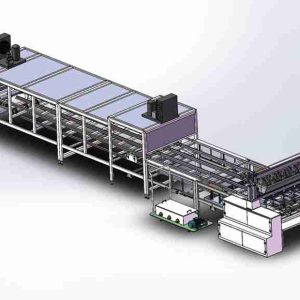

Our Liquorice Candy Production Line is a sophisticated solution for manufacturers seeking to produce a variety of licorice and soft candies with efficiency and consistency. This line is designed to cater to the creation of classic licorice candies, as well as innovative products like Sour Belt Candy and multicolored sugar coated sour belt chew candies.

Key Components:

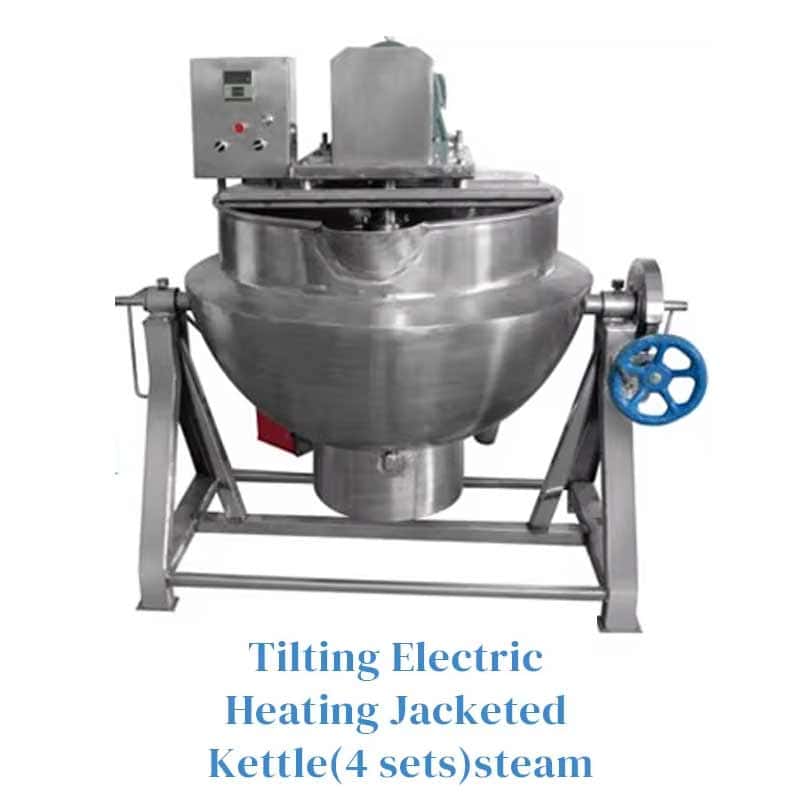

- Jacketed Cooker: Ensures even heat distribution for perfect candy texture.

- Gelatinized Starch Machine: Prepares the base for a wide range of candies, including licorice.

- Extruder: Crafts candies into traditional shapes or innovative forms like the iconic Sour Belt.

- Jelly Pump: Dispenses jelly for soft candy strips and Rainbow Belt Gummy Sour Candies.

- Powder Mixer: Integrates sour powders for a tangy center in candies.

- Cooling Tunnel: Sets the texture and shape of the freshly extruded candies.

- Steam Sprayer: Adds the perfect touch of moisture for a soft candy strip.

- Cutting and Forming Machine: Precisely cuts and forms candies for uniformity and appeal.

Range of Application: This production line is not only suitable for traditional licorice candy but also for creating a spectrum of sour belt candies, including the vibrant Rainbow Belt Gummy Sour Candy. The versatility of the line allows for the production of soft candy strips in various shapes and sizes, all customizable to include sour or sweet fillings as per customer requirements.

Features and Benefits:

- Versatility: Produces a wide range of licorice and sour belt candies with ease.

- Customization: Adjusts to create candies with powder or jelly centers, and in various shapes and colors.

- Efficiency: High production capacity to meet the demands of the market.

- Quality: Consistent texture and flavor due to precise control over the production process.

- Safety: Equipped with safety features for a secure production environment.

- Ease of Operation: User-friendly interface for hassle-free production management.

Quality Assurance: Our Liquorice Candy Production Line adheres to the highest quality standards, ensuring that every candy produced meets consumer expectations for taste and texture.

After-sales Support: We provide comprehensive after-sales support, including a warranty, maintenance services, and a reliable supply of spare parts.

Pricing and Availability: For detailed pricing and availability, please contact our sales team for a personalized consultation.

Dive into the mesmerizing world of licorice candy production, where the rich history of this ancient sweet meets modern manufacturing techniques. From the earthy goodness of its natural flavor to the chewy delight it brings, licorice candy has a unique place in the confectionery universe. This extensive production description will guide you through the intricate process of creating a licorice candy production line, from ingredient selection to the final packaging.

1. Sourcing and Preparation of Ingredients

The journey of licorice candy begins with the careful sourcing and preparation of its key ingredients. The primary component is the extract from the roots of the Glycyrrhiza glabra plant, commonly known as licorice. This extract provides the candy with its distinctive taste and numerous health benefits. Other ingredients include sugar, corn syrup, and various flavorings and food-grade colorings to enhance the final product.

2. Cleaning and Roasting Licorice Roots

Upon receipt, the licorice roots undergo a thorough cleaning process to remove any dirt or impurities. They are then roasted to bring out their natural sweetness and to prepare them for extraction. This step is crucial as it affects the flavor profile of the final product.

3. Extraction of Licorice Flavor

The roasted roots are then processed to extract the valuable licorice flavor compounds. This is typically done through a solvent extraction process, which separates the flavor compounds from the plant material.

4. Mixing and Cooking

In the next stage, the extracted licorice flavor is combined with sugar, corn syrup, and other ingredients in large mixing vessels. This mixture is cooked to precise temperatures to achieve the desired consistency and texture. The cooking process also helps in caramelizing the sugars, adding to the candy's flavor.

5. Flavoring and Coloring

Once the basic licorice mixture is ready, it's time to add specific flavors and colors. Whether it's traditional black licorice or the more vibrant red, green, or yellow varieties, food-grade colorings are added to achieve the desired hue. Flavorings such as anise, mint, or even chocolate can be incorporated to create a wide range of licorice candy varieties.

6. Cooling and Pulling

After the mixture reaches the appropriate temperature, it is cooled and then pulled. The pulling process is a traditional method that involves stretching and folding the candy to introduce air, creating a chewy texture. Modern production lines may use automated pullers for this task, ensuring consistency and efficiency.

7. Cutting and Shaping

The pulled licorice is then cut into the desired shapes and sizes. While traditional licorice is often in rope form or twists, modern production lines can create a variety of shapes, such as rounds, wheels, or even novelty forms.

8. Drying and Hardening

The cut licorice pieces are placed on racks and allowed to dry and harden. This process can take several hours and is essential for achieving the candy's final texture. In some cases, a controlled environment with specific humidity levels is maintained to ensure uniform drying.

9. Quality Control and Inspection

Each batch of licorice candy undergoes rigorous quality control checks. This includes visual inspections for appearance, texture, and size, as well as taste tests to ensure the flavor is consistent with the product specifications.

10. Packaging

The final licorice candies are then packaged. Depending on the product, this can range from simple plastic wrapping for individual pieces to more elaborate packaging for gift sets or bulk sales. Modern packaging machinery ensures that the candies are sealed in a way that preserves their freshness and quality.

11. Storage and Distribution

Proper storage is critical for maintaining the quality of licorice candy. The packaged candies are stored in a cool, dry environment before being distributed to retailers or exported to various markets.

Statistical Data

The global licorice market is estimated to grow at a CAGR of 4.1% during the period 2020-2025, indicating a robust demand for licorice products worldwide. This growth is driven by the increasing recognition of licorice as a healthy snack option and its unique taste profile.

FAQS

When considering the purchase of a licorice candy production line, potential buyers often have a variety of questions to ensure the investment aligns with their business needs. Here are some pertinent questions that can guide them through the decision-making process:

- What is the capacity of the licorice candy production line?

- Understanding the production line's output capabilities is crucial for meeting market demands and planning production schedules.

- How versatile is the production line in terms of candy shapes and sizes?

- Knowing the range of products the line can produce helps in determining whether it can satisfy diverse consumer preferences.

- What are the total costs involved, including the purchase price, operational costs, and maintenance?

- A comprehensive understanding of all associated costs is essential for budgeting and return on investment (ROI) calculations.

- What types of licorice flavors and colors can the production line accommodate?

- Flexibility in flavor and color production can impact the variety of products offered.

- Does the production line comply with international food safety and quality standards?

- Adherence to standards like ISO, HACCP, and FDA regulations ensures product safety and marketability.

- What is the level of automation offered by the production line?

- Automation can significantly impact efficiency, production speed, and labor requirements.

- What kind of training and support does the manufacturer provide for operating and maintaining the equipment?

- Adequate training and ongoing support are vital for the smooth operation of the production line.

- What are the warranty terms and after-sales service options?

- Knowing what is covered and the availability of service can provide peace of mind regarding potential future issues.

- Can the production line be customized or scaled up to meet growing business needs?

- The ability to adapt the production line to changing business requirements is an important consideration.

- What is the typical lead time for delivery and installation of the production line?

- Understanding the timeline for setup can help with planning and meeting market entry deadlines.

- Are there any energy efficiency features in the production line that can reduce operational costs?

- Energy-efficient machinery can lead to long-term savings and contribute to environmental sustainability.

- How does this production line compare with competitors in terms of performance, reliability, and price?

- Comparative analysis can provide insights into the best value for the investment.

- What financing options or leasing opportunities are available for purchasing the production line?

- Flexible financing can make the acquisition more manageable.

- Are there any additional costs for raw materials, packaging materials, or consumables used in the production process?

- Factoring in all material costs is important for accurate financial planning.

- What is the expected lifespan of the production line, and what is the process for upgrading or replacing components?

- Understanding the longevity and upgradeability of the equipment can impact long-term business strategy.

By addressing these questions, potential buyers can make a well-informed decision about investing in a licorice candy production line that suits their business goals and operational requirements.

Contact Us

Are you intrigued by the process of creating your own licorice candy empire? Explore the market further, understand consumer preferences, and consider investing in a licorice candy production line. With the right combination of ingredients, equipment, and passion, you too can bring the joy of licorice to candy lovers everywhere.

Why Choose Us?

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.

Reviews

There are no reviews yet.